|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,761. Welcome to our newest member, AnicaLin

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

I can’t find the thread now, but some time ago someone requested the various distances and resulting angles for the sharpener. The length gauge that you received with the fixture is 1-Ľ long. It will produce a 45 degree face, 16.3 degree high heel. If you instead lock the graver in so it is protruding 1-5/8” it will make a 41 degree face with a 14 degree high heel. Setting the length to 7/8” will produce a 50 degree face with a 19.5 degree high heel. The measurement is from the shoulder on the sharpener. Check where the shipped length gauge measures from. That is the shoulder to measure from. If you’re grinding one of the uniform-parallel heeled gravers be sure to grind the long relief grinds on the bottom of the graver as well as the small heel and the face with the graver sticking out the same length so the heels come out uniform.

1.625" = 41 face, 14.0 high heel 1.250" = 45 face, 16.3 high heel 0.875" = 50 face, 19.5 high heel Sharpening instructions

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#2

|

||||

|

||||

|

Thanks Steve, this helps allot...

I had ask before if I set the diamond stone off the large blue square and set it on the table below that would change all the angles, especially the heel... Your info is so much better than my guessing... Jerry |

|

#3

|

||||

|

||||

|

Hi Steve

I want to thank you too! As a "newbie", I appreciate it when someone takes the time to answer dumb questions as you did in a recent e-mail. I have learned enough, so far, to realize that the information posted in this thread can be used to make the sharpening fixture much more versatile. As for now, this info is being filed away until such time as I am satisfied with my control of a graver. |

|

#4

|

|||

|

|||

|

Thanks Steve,

I will have to make use of the convertion table now. Cheers "VAN" |

|

#5

|

||||

|

||||

|

Printed off for my records. I'll have to make (and label) a set of guages.

|

|

#6

|

||||

|

||||

|

Good, glad it helps. I did made an adjustable length gauge. The fixed length gauges do seem to be more quick and repeatable during use.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#7

|

|||

|

|||

|

thanks, steve. i had asked sometime ago about this very thing. good to know about the 50 degree one. thanks again.

|

|

#8

|

|||

|

|||

|

What length for 55 and 60 degrees

|

|

#9

|

||||

|

||||

|

Hi Toad, I don't know without pulling up the cad file to calculate exactly. But it would be shorter than .875" since that is 50 degrees. .750" I bet would be pretty close and it is an easier number to remember. Instead of going shorter with the length that the graver is sticking out we can instead just raise the height that the template sets or lower the stone height. Or you can do a combination of both. Whatever you do, do it for all the facets (small and large template) so that the heels come out parallel.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#10

|

||||

|

||||

|

Hi Steve, since you opened my eyes of using a much shorter heel, problems with heeldrag became much less.

But for example heavy cuts of small curves which are tapered on a short way to both ends still causing heeldrag from time to time. Maybe it’s my personal and wrong way of holding the airgraver?! When I try to come out of the metal ( heel really is short) I often scratch the outer edge. Could 0.875" = 50 face, 19.5 high heel be a better angle for me or could I try something different? With the naked eye it’s all nice, but with magnification it’s not yet perfect Best regards Ralph Rene |

|

#11

|

||||

|

||||

|

Quote:

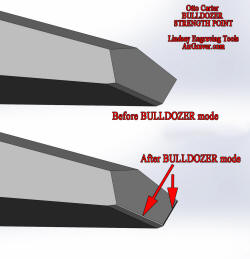

Yes, steep face and wide V will be a stronger point. Also dubbing the point. Dubbing is described clear at the bottom of this page: https://www.engravingschool.com/priv...0Sharpener.htm  Also Bulldozering the two cutting edges. Similar to dubbing but instead of the point you do it to the two cutting edges.   I have another 116 degree template that has a 50 degree face. Also thanks to Rick Simmons and Wes Griffin there is another set that is steeper yet. They are at the top of this page link: "Friction" https://www.airgraver.com/news.htm

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#12

|

||||

|

||||

|

Hi everybody,

for all goldsmiths out there practicing inside ring engravings I just want to share what I found out. For all new engravers like me it’s very frustrating inside rings without perfect graver control. Cuved surface, limited clearance and very small script letters often ending up in heeldrag. Gravers sharpened with the 22.2 mm length gauge gave me a completely different feeling compared to the normal ones. I immediately got a much better result, nice small letters without any heeldrag. If you are a beginner like me, you definitely should try it with a length gauge of 22.2 mm. It helped me A LOT! |

|

#13

|

||||

|

||||

|

Quote:

![Smile[2]](/images/smilies/top smiles/smile[2].gif) You must then be at around a 50 face and 20 high heel. You must then be at around a 50 face and 20 high heel.0.875" = 50 face, 19.5 high heel

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

| Bookmarks |

|

|