|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,762. Welcome to our newest member, Katherine

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

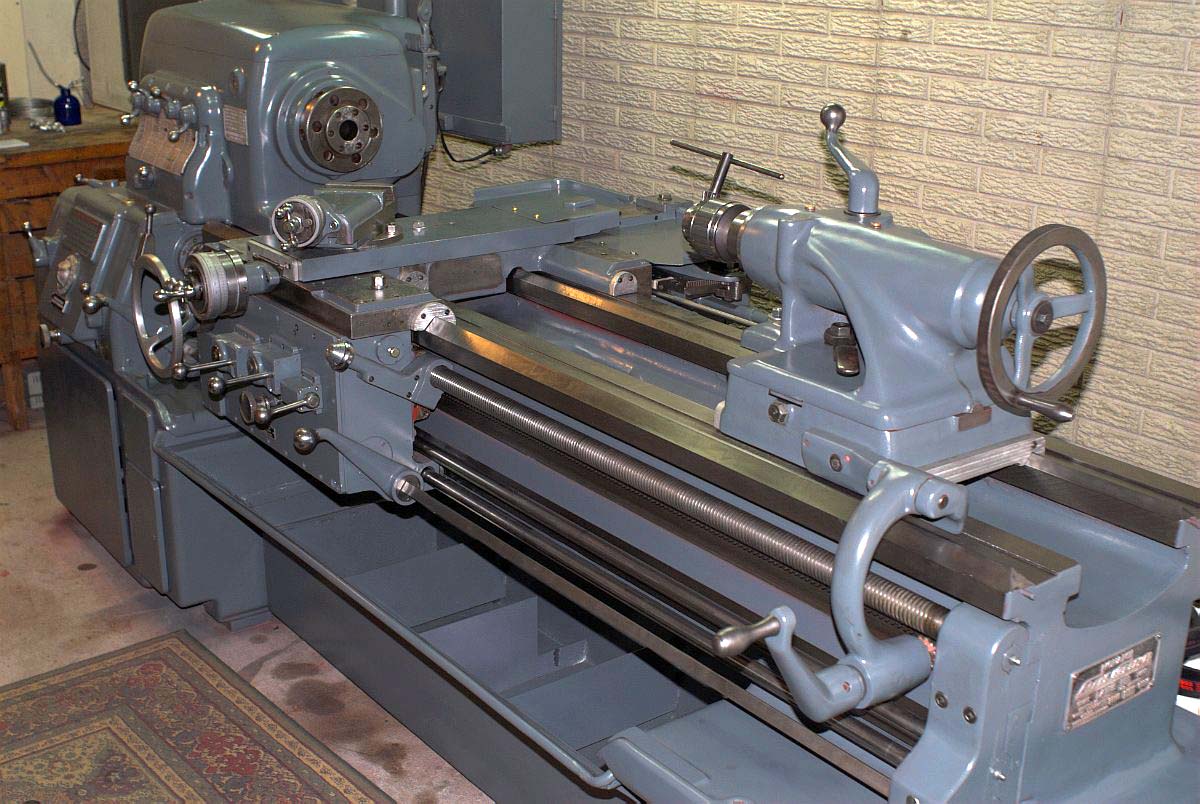

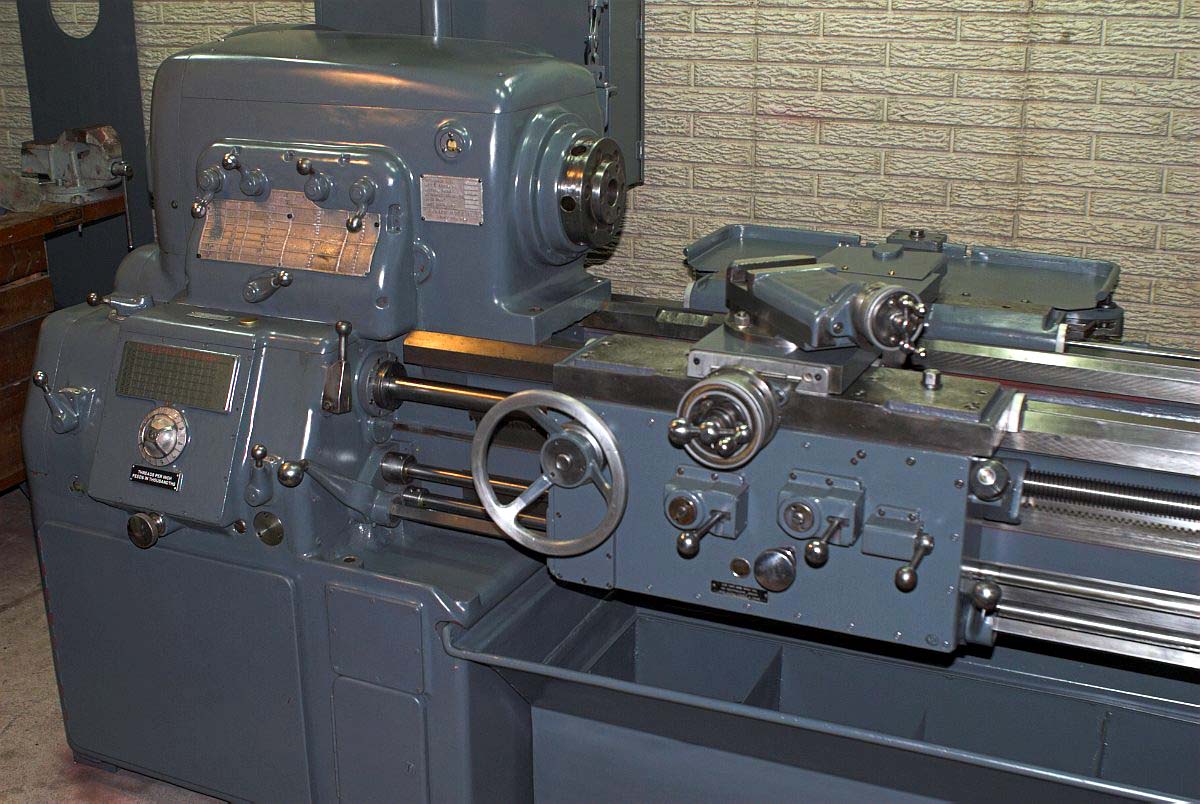

Here are shots of the completed Monarch lathe project.

I've been on and off of it since January.   Here is a link to a bunch of progress pictures during the restore. http://www.lindsayengraving.com/tour...20restore.html

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#2

|

|||

|

|||

|

Goodness Steve, It looks like you have a working museum there! You also appear to be able to maintain 2# in a 1# container.

It would be fun to see the coining press in operation. It would be fun to see the coining press in operation.gailm |

|

#3

|

||||

|

||||

|

Steve, :whoo:

Very Nice, Now I need to do the same to my Logan. Did I hear you say you were going to volunteer to help. (ha ha ha)  JT |

|

#4

|

|||

|

|||

|

WOW!! That is amazingly cool....youll have to share some tips someday...Id love to refurb an old Hardinge and Springfield lathe of mine...

|

|

#5

|

||||

|

||||

|

DANG! That looks better than my truck!

Another fine restoration by Lindsay Machine Salvage Co. Inc. LTD, LLC. HMO. CDL. LMNOP!  It's nice to know that it'll get good use in your shop instead of just sitting there looking new. That ought to make a bunch of Glide Lock vises! Can't wait for the contest to win one of those babies...

__________________

"If one needs a tool, and does not acquire it, they end up paying for it, but not having it." - Henry Ford |

|

#6

|

||||

|

||||

|

That's a looker all right! :thumbsup:

It's good to see a tool as nice as that back in use (and back in shape since it was somewhat less 'nice' when you started). How much was repairing and how much was just plain cleaning? |

|

#7

|

||||

|

||||

|

Thanks for liking it.

![Smile[2]](/images/smilies/top smiles/smile[2].gif) Steve, It was probably 75% cleaning and 25% repairing. The bottom of carriage had turcite on it already. This probably saved the bed because the oiling system was plugged up. I glued .015" thick turcite to the bottom of the cross slide and scraped it flat using a surface plate. Then used it to fit to the mating slide on the carriage. The dovetail on the left side of the slide was worn with a bow. Got it scraped out straight and had to add another .010" shim to the gib along with the .015" high turcite. Rapid transverse gears were worn and had new gears made for that. Bearings in the clutch were bad. Also replaced the 16 bearings in the taper attachment. Several bronze plain bearings were pressed out and replaced. Replaced the restrictor valves for the oiling systems in the carriage, gearbox and head. There was one restrictor between the gearbox and head that was challenging to replace. The spindle bearings a pervious owner already replaced, so that is good. Found a time clock factory ticket used as a shim in the carriage. It had a date of 1983 written it. So I assume this was the last time it was gone through and the turcite was added to the bottom of the carriage. I used bondo lacquer spot putty for filler. Probably 50 tubes to fill the rough castings. Smear it on and then sand most of it off and then do it again. Paint is from a can. Maybe 15 cans of primer and 25 cans of paint. Krylon #1611 Universal Gray Engine Paint. It is a little more of a darker blue grey compared to other grey machine paints I can find in a can. I've decided it easier using can paint simply because it is so easy to repair. I keep extra around along with the spot putty, and it is fast to repair damaged paint.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#8

|

||||

|

||||

|

Thanks for the details!

Looking at the progress pictures you don't really notice how rough the surfaces were when you got it, just how smooth they are now (the change from old, cruddy paint to glossy newness is part of that). Sounds like you've got it ready for another 50+ years of use. ![Smile[2]](/images/smilies/top smiles/smile[2].gif)

|

|

#9

|

||||

|

||||

|

You have WAY too much fun. Saving that old iron is a special thing to me. The machines should last literally forever, thanks for savoring the feel and preserving them. They won't be made ever again.

![Smile[2]](/images/smilies/top smiles/smile[2].gif)

__________________

Remember, it could well be that your only purpose in life is to serve as a warning to others. ![Smile[2]](/images/smilies/top smiles/smile[2].gif)

|

|

#10

|

||||

|

||||

|

Don't be too sure - with that lathe Steve could make another one just like it.

I read that somewhere the lathe is the one machine tool that you must have if you want to make a machine shop - you can make all the other tools with a lathe but it's very hard to make a lathe without a lathe. Apparently you have to keep using your current lathe to make a better version until you cross a threshold. |

|

#11

|

||||

|

||||

|

[quote=Tim Wells]DANG! That looks better than my truck!

quote] Tim, How is the mill restore project coming. Is it getting close?

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#12

|

|||

|

|||

|

hey Steve, how hard is it to install that turcite?

|

|

#13

|

||||

|

||||

|

Hi Pat, The turcite is glued on with epoxy. Clean the metal super good, cut the turcite to size and glue on. Since it was on the bottom of the slide that was a flat portion of the dovetail I glued it on and before dry, set it down on a large surface plate with maybe 100 lbs of weight on top, so that it would hopefully glue on close to flat. After dry, use marking blue (similar to printers ink) with the surface plate to find the high spots and scrape the trucite for sure flat.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#14

|

|||

|

|||

|

Sounds simple enough...the hardinge i have is a second op lathe with the reverse dove tail (similar to your TL) and the bed is worn where the saddle has just taken its toll...no one in my area can surface grind anything this long. The wear is in the 0.005" range, do you think the turcite would be a good solution to rebuild this bed? Or should i just suck it up and scrape the entire bed.

|

|

#15

|

||||

|

||||

|

That hardinge TL tool room lathe I have is a reverse dovetail and was worn with a .005 hole next to the head stock. I ended up setting it up on the mill and trued it up that way. (fly cutter and 60 degree angle cutter) The bed was almost too big for the mill table and on the ends the weight on the table made a .0005 to .001" bow up in the middle of the bed. I scraped and stoned that down. The setup in the mill was several days of checking, shimming and indicating to get it lined up before taking a cut.

I wouldn't put turcite on the top of the bed. On the underside of a carriage or a slide where it is more protected is usually where it is used. There are machine rebuilding companies I've see on the net. Maybe contact some and see what it would cost for them to grind the bed. A large planer is sometimes used on longer beds too. It is similar to a shaper but the work table moves and the cutter is stationary.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#16

|

|||

|

|||

|

^^thats exactly what I was going to do to at least *rough* it down prior to any scraping action. Ill have to tighten up my table on the mill, Ill get around the same bow the cut with the table taken to its extreeme ends for the pass...and I really dont look forward to indicating that thing on the table.

Too bad my CNC isnt big enough to cut this thing, that would make life so much easier ![Wink[1]](/images/smilies/top smiles/wink[1].gif)

|

|

#17

|

||||

|

||||

|

Steve, I have a 1956 Leblond Regal that looks very similar, I have had it for quite a few years and it is in very good shape. I am tempted to strip it and repaint it from time to time but never seem to get there. One of these days.

Neil:yesnod: |

|

| Bookmarks |

|

|