|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,762. Welcome to our newest member, Katherine

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

|

|

#2

|

||||

|

||||

|

Just sold for (I've converted it for you folks across the pond) $76,000.

Yes, Willard Wigan is a clever guy. He's from the same city as me. |

|

#3

|

||||

|

||||

|

Amazing, Next morning he must having a beard....

|

|

#4

|

||||

|

||||

|

The tools are very fine Victorian needles which I rub down on an arkansas stone and push into a wooden graver handle. I bought them from an antique dealer many years ago. They have gold eyes. The quality is superb. The difficult part is hardening and tempering the needle. It's so thin that I only have to show it to a candle and the heat flies along it. I don't have a lot of control in this - it's hit and miss most of the time. Next year I'll have been engraving for 50 years. I think that will be long enough. My eyesight is now failing. I have a regular course of botox injections around my left eye because it has been affected by strain. This helps, but sadly, the wrinkles are still there!

|

|

#5

|

||||

|

||||

|

Quote:

Quote:

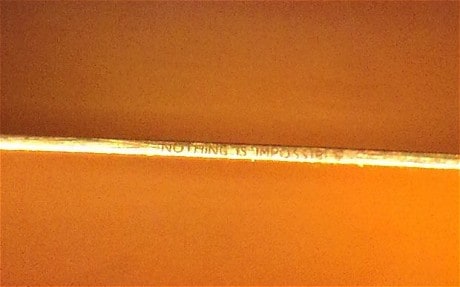

I hope your eyes can hold out and you can keep on micro engraving! It is great what you're doing. This looked like a fun challenge, so I tried lettering the edge of a razor blade this afternoon. ![Smile[2]](/images/smilies/top smiles/smile[2].gif) It was unclear to me in the writeup and picture if the engraving is on the cross section of the blade adjacent to the cutting edge or if it is on the cutting edge itself. If on the cutting edge, there is no flat area there to engrave unless the sharp edge were stoned. Anyway, I tried lettering one of the edges adjacent to the cutting edge to see how it would go. ![Smile[2]](/images/smilies/top smiles/smile[2].gif) I left the engraving bright and didn't blacken it in. The letters measure around .005" high. This block lettering is similar to the signature engraving I used on the border of a knife engraving if there isn't a place for it otherwise. I don't try and cut lines for this small lettering, but just make dots with either a bulino graver or a sharpened carbide scribe and use it similar to how scrimshaw is done with dots. You can make a precise tiny carbide needle points by starting with a 1/16" carbide dental bur. Sharpen in the NSK presto handpiece by holding the bur on a 600 diamond bench stone or diamond lap. Once you have it to a point with this grit, then with it running take it to the 2000 diamond bench stone for a final finish. This is what I made this afternoon for the lettering and then held it in a pin vise. The points can be made long and thin this way or less slender if needed for a stronger tip. In one of the knife engraving videos there is a recording of the process while engraving the signature. It was done the same way. I'll look for it and post it here.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#6

|

||||

|

||||

|

Found that video. The signature process is the last two in this video series.

It starts about 1/4 of the way through the 2nd to the last video and goes into the last one. I'm laying the letters out first by scratching and then going over it with the dots. Graham, Can you post some picture of your needles and handles you use? It would be great to see a video to watch you work too. If you have a video or pictures I can help you post them. _____________

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#7

|

||||

|

||||

|

Quote:

(Steve, the engraving is along the sharp edge. You are right, the blade had to be prepared to get a flat edge) |

|

#8

|

||||

|

||||

|

Quote:

Quote:

Thanks for the replies Graham. How large of flat are you placing on the cutting edge? Or in other words what is the height of the letters? I am interested in trying it some more. Would it be possible to talk you into placing a single letter on the edge of a razor and send it to me so that I can see the size you are at first hand? It would be helpful. In trade I could sharpen you a couple carbide needle points using the dental rotary handpiece on a diamond lap. If the needles you are using are very old as you mentioned they would probably be made from carbon steel. You may enjoy checking out needles made from HSS, M42 cobalt or carbide. The write-up mentions that the engraving can only be seen with a 400x microscope but later it says you are using magnifying glass for the work. What power is the magnifier? Is it a hand held magnifier? Thanks again. ![Thumb[1]](/images/smilies/top smiles/thumb[1].gif)

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#9

|

||||

|

||||

|

Guys, it's only the last few years I've realised that this miniature work is being regarded as an art form. The magnification has been 'magnified' by the press along the way! I think the confusion was caused because when journalists came to see the microscope I use. They could see it has a maximum 400x magnification. I work under a microscope, not a glass, much less than 400x, and when the finished job is viewed it is set in a domed case under a 30x or 40x microscope.

I've been working on steel pins for years, but again, it's only recently I've started using gold pins. Much easier to work on. Last year I finished a portrait of our queen on a grain of rice. not so much a caricature, but a real drawing of her, showing her hair and the jewels in her crown. For some reason, this didn't get the publicity I'd hoped for. I now have an agent managing my affairs and everything is going well. (Steve, the flat I put on the blade is as large as I can get away with!) I couldn't do it without. |

|

#10

|

|||

|

|||

|

Steve mentioned the razor blade he engraved on was 0.005" which is 0.12mm by my reckoning. Graham suggests his blade was 0.1mm.

Looking at Graham's 15 line engraving of the Lords Prayer, on a 2mm pinhead, with generous line spacing would be (as a guess) less than 1mm in height of each letter. My guess would be .8mm letter height but that is a best guess. It would of course be great to have some very specific sizes. Just off topic ever so slightly, How about a letter 5 atoms high? http://www.sciencemuseum.org.uk/ante...urself/153.asp

__________________

++++ What would you attempt if you knew you could not fail? |

|

#11

|

||||

|

||||

|

Quote:

Quote:

The thickness of the razor blade I engraved measures .009". The lettering height I was estimating .005" with a .002" border on each side. If it is closer to .0015" then it would be .006" high. I timed the lettering. It took 12 minutes but not including the time to make the carbide needle. It went quicker than the knife lettering video since there was less area to cover, plus I was trying to go quick since it was being timed. ![Smile[2]](/images/smilies/top smiles/smile[2].gif) I think most razor blades are hardened. 55rc? Unless the blade is annealed it would probably be close to the hardness of a carbon steel point. I didn't anneal the blade since carbide would be harder than the razor blade. To make it easier anneal the blade first by using a torch or since the blade is so thin a candle flame to heat it up and let it air cool. That would soften it. Then polish the edge with fine sand paper.  Chris that is pretty cool about the lettering with atoms link! Here is something else. Check out this microscopic mechanical motor. It runs on bacteria! http://www.livescience.com/7112-mach...-microbes.html _____________________

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#12

|

||||

|

||||

|

Interesting stuff

![Thumb[1]](/images/smilies/top smiles/thumb[1].gif) Maybe i`ll screw up some micro pave long enough to justify charging some ludicrous money... Not sure if that`ll wash but worth a try ![Biggrin[1]](/images/smilies/top smiles/biggrin[1].gif)

|

|

#13

|

|||

|

|||

|

This is fascinating, and I would love to know the real dimensions involved.

__________________

++++ What would you attempt if you knew you could not fail? |

|

#14

|

|||

|

|||

|

Steve,

It has intrigued me too. I have seen photos of the lords prayer on a pinhead and often wondered how it was done and the steady hand needed to achieve such fine work. Now the edge of a razor blade that's cool. Keith |

|

#15

|

||||

|

||||

|

Quote:

Quote:

Edit: Hey.. another thought to figure out scale since he isn't saying. Graham mentioned a 30 to 40x scope. With this we may be able to have a closer idea of text size by zooming our scopes to that power and matching the size in the press photo to use as scale. Maybe just zooming in to that power on a fine graduated ruler could work and measuring the field of view at that scale. That would give the approx distance from one edge of the photo to the other. Figuring it that way the letter height comes out around the .005". This means the edge of the blade we are looking in the photo must be the full width of a razor blade without the edge which correlates to Graham's reply when asked how much of the cutting edge is ground or stoned away to make a flat area to provide a place to put the letters on: Quote:

Okay, maybe makes sense and the above photo of Graham's is of the full thickness of the blade after the cutting edge is sanded away. I can see slight rounding of the surface along with a few sanding or stoning scratches left. I didn't anneal the one I did in the timed 12 minutes, but if others try it you could first heat the razor blade to a dull red and let air cool. A torch or just a candle should work since the metal is so thin. This will make the metal softer and easier to engrave. Now stone or sand away the cutting edge and engrave. Or engrave the side edge of the blade. ___________

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#16

|

||||

|

||||

|

UPDATE:

I noticed Graham edited each one of his posts in this thread and removed pertinent information in the discussion. Luckily the forum makes automatic backups so that this thread and posts were recovered. When someone backspaces over his posts in a thread, it makes the thread meaningless because the content that we are discussing is taken away. This is a forum about learning to engrave and helping each other. Forum polices in part: "Posts that are entered on the forum become part of this archive and will remain there indefinitely as a resource to the public. "

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

| Bookmarks |

|

|