|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,762. Welcome to our newest member, Katherine

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

This is my workshop. I pass all my time in this space.

8 to 10 hours by day ;-)  And you how many time do you pass in your work space by day?

__________________

http://rbaptiste.com |

|

#2

|

|||

|

|||

|

I like your arm rest. I will have to try that. Your bar setup is also nice.

Jack Jack

|

|

#3

|

||||

|

||||

|

Thanks!

The arm rest is very confortable for working. Your hand have less vibration with that, you have more control. Attention you must regulated the height with your work to have a very good positionning.

__________________

http://rbaptiste.com |

|

#4

|

||||

|

||||

|

Roland, I envy your workspace. I especially like all the wood and the lighting from the windows.

![Smile[2]](/images/smilies/top smiles/smile[2].gif)

__________________

Remember, it could well be that your only purpose in life is to serve as a warning to others. ![Smile[2]](/images/smilies/top smiles/smile[2].gif)

|

|

#5

|

|||

|

|||

|

Here's mine so far,

But I've got one of these coming!!!!!!!!     The only difference in mine is my scope boom is different and I'm having a table top put on & will have some drawers underneath the counter top. :yesnod: I can wait to get it. I struggle with my back & neck, so my time at the bench is limited, When I first sat down at this thing I was totally amazed! You can literally change the set up & be cutting from someone elses settings in a few minutes. Amazing, they can be custom built to your specs. Dwayne

__________________

www.dushaneknives.com ddushane@suddenlink.net Romans 8:28 And we know that all things work together for good to those who love God, to those who are the called according to His purpose. |

|

#6

|

|||

|

|||

|

That looks like a slick setup! However, I would be annoyed by the long legs protruding to the front. I'd shorten those significantly and then increase the weight in the back accordingly. Like a sand box welded to the frame, so it still can be moved some day. With my long leg's I'd be banging into them all day 8).

Man, I am having tool envy just looking at that station. congratulation's! Rainer |

|

#7

|

|||

|

|||

|

Rainer, I've already talked to them and they are shortening the legs on mine. I'm hoping I won't have to move it once in place but you never know. I'll have to bribe someone into moving it for me.

__________________

www.dushaneknives.com ddushane@suddenlink.net Romans 8:28 And we know that all things work together for good to those who love God, to those who are the called according to His purpose. |

|

#8

|

|||

|

|||

|

Here are four pics of the main work area in the studio. There is a shot of my main bench. A shot looking at the left and one looking at the right sides of my bench. and a shot of the drawing tables on the opposite wall behind my bench.

In the pics you can also see parts of student stations behind my bench. Yes, I do sometimes have the TV on listening to the news or DVD movies when I work. I am considering putting in surround sound :whooho: Ray |

|

#9

|

|||

|

|||

|

Quote:

Rainer PS:The square tubing looks heavy. No joke, that's at least 150-250lbs. |

|

#10

|

|||

|

|||

|

Ray, You're just spoilt, that's all there is to it

& I'm trying to be the same way, Hope Mama don't run me off. & I'm trying to be the same way, Hope Mama don't run me off. Rainer, The square tubing is Heavy and there is no vibration at all that I could tell, now cutting the legs short on the front side made me think of the leverage most of all because the table for the engraving block is 3/4" thick, very solid, the sand box may be the way to go. Like I said earlier, I'm having a table top built for mine. Not sure if I'll have them put drawers on it or do that myself but the the table top along with my graver max and sharpening hone and other items will probably stabilize it that much more. I've looked at everyones pictures that have been posted here and on the Engravers cafe. Several people have some nice looking work stations, I'm looking forward to getting this one in and trying it out. Dwayne

__________________

www.dushaneknives.com ddushane@suddenlink.net Romans 8:28 And we know that all things work together for good to those who love God, to those who are the called according to His purpose. |

|

#11

|

|||

|

|||

|

Hi guys! Just had to yack at yall about this New Dulin-Hawk Engraving platform, I just got mine in this evening and got it set up around 11:00 this evening, would've been sooner but I couldn't unload it and bring it into my shop, called and got a couple of police officers to come help a brother out, and wa la! I got it all set up and was engraving pretty durn quick. Like a said in a previous post, I struggle with my neck & back, This is one of the answers! I love it, just set the scope for your personal hight and just with a push of a button the table and ram raises with ever so light a nudge with your knee, the work raises right into focus, it's exactly what the Dr. ordered. I love it!!!!!! mine is a different color than the one I posted pictures of that I tried at Shanna's house and my scope boom was a little different that Shanna's so they modified mine from the original design to accommodate my scope. Some guys also mentioned the legs coming out to far, they shortened mine and I do like them shorter, it wasn't that big a deal for me cause my chair has casters but they are out of the way more now. Take a look, and if you want to try it out just come to Andrews and play on it. Later, Dwayne

__________________

www.dushaneknives.com ddushane@suddenlink.net Romans 8:28 And we know that all things work together for good to those who love God, to those who are the called according to His purpose. |

|

#12

|

|||

|

|||

|

I just get on the forum and I present to you a my turn my bench

. |

|

#13

|

||||

|

||||

|

I'm curious about the turn table base used on Ray Cover's set up. I'd like to add a 12" to 14" diameter turntable base to my set up and need to know where to find such a turntable. Here are some of my jewelry store pic.s on file. It's a small space like a rock and hard place but the windows are good. The picture of me is when I was experimenting with being fat like Al Gore but since then I have lost 20lbs. to put less drag on the planet.

The bottom photos are of my home basement shop where I do all the wax carving and engraving layout work. All the metal work and engraving is done at my store. I also do a little painting and have a 400 watt high pressure sodium grow light for plants and sunshine in the basement. I'm currently doing a basement insulation project so it's a little jumbled down there.         Here is a current painting in progress. It takes me about 5 years of spare time (occasional Sundays) to complete a painting.  This is the last one I finished

|

|

#14

|

|||

|

|||

|

J, they have the turntable but it's only 10" in diameter, don't of one made like this that is bigger, maybe someone in the forums knows of one larger, I have a lapidary machine just like the one on the right side of your second picture, haven't set it up yet but will one day, want to put stone in my knives at some point. Thanks for posting the pics, good luck with the turntable. Dwayne

__________________

www.dushaneknives.com ddushane@suddenlink.net Romans 8:28 And we know that all things work together for good to those who love God, to those who are the called according to His purpose. |

|

#15

|

||||

|

||||

|

Jroegtter;

If I remember right, Ray is using a drill press base and table. By the way thats a nice old Highland Park unit, used to have one similar, except mine had the trim saw on the left end. |

|

#16

|

|||

|

|||

|

J,

I have both the drill press type and the gas piston type of turntable here at the school. The one on my personal bench is the gas piston type. This was basically made by putting a lathe face plate on top of a gas lift piston out of an adjustable bar stool. I have also mad ethem out of the pistons from office chairs and it works fine you just don't get as much height adjustment as you do from the bar stool. If you decide to got his route there are some things to keep in mind. - you need to make a bushing tfot he bottom of the piston to take the play out. - since most chairs sit at a slight cant you will need to shim up on end of your face plate base with washers to make it level. Ray |

|

#17

|

||||

|

||||

|

Thanks for the turn table info. It would seem like one could automatically have a centering vice using a set up like that. Just move the ball vise around and voila. I really like the lapidary for hogging down tools. I removed the trim saw because of space limitations. Working stone takes a special character because just when you are about finished spending two hours on a stone a little flaw can appear as your polishing it and spoil the whole thing. Metal is so wonderfully predictable by comparison.

|

|

#18

|

||||

|

||||

|

I like the pictures of your shops guys and gals. I learn alot just by looking at another persons shop. You never know what ideas you will pick up.

Neil:yesnod: |

|

#19

|

||||

|

||||

|

Hey All,

I am new to the engraving world. Here is a pic of my bench that I just put together in the house last week. I am still waiting for some more equipment to come in, but for now it's nice and neat. Jay |

|

#20

|

||||

|

||||

|

Just wait, if you are like the rest of us junkies your bench will be filled with tools and projects to overflowing in just a few months.

Neil:yesnod: |

|

#21

|

||||

|

||||

|

Yeah, you can tell Jay hasn't started working yet - that bench is way to clean and clear!

Give him a couple of weeks and he'll have a nice layer of 'stuff' on it. |

|

#22

|

||||

|

||||

|

Jroettger

This is a stand that I have found on the forum that someone posted. It looks like it will do just as good...Take a LQQK.  http://www.cabelas.com/cabelas/en/te...equestid=77461 |

|

#23

|

||||

|

||||

|

Hi Everyone,

I finally have my bench clean enough to post a picture of it. The desk top is 3" oak boards stacked on edge. Thing weights a ton, but is rock solid for engraving. Cheers, JT |

|

#24

|

||||

|

||||

|

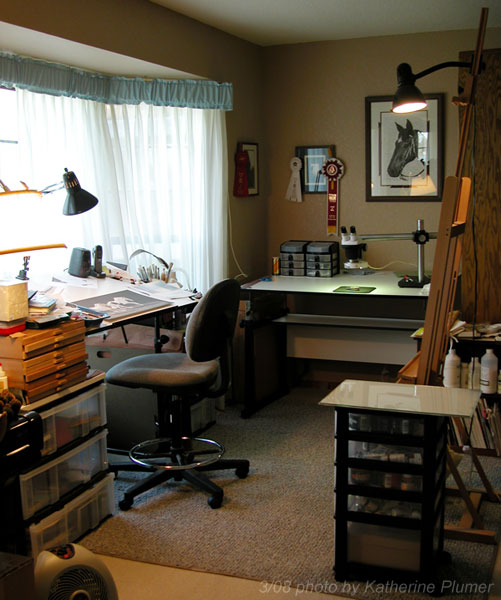

My studio doesn't look like anyone else's studio. I guess if I was working with metal or power tools I'd be banished to the barn but for now I attempt to keep my artistic creativity (in other words the incredible mess that I make) confined to a corner of the living room...

This is "Studio 3.0" the most recent configuration. It's abnormally tidy in this photo because I'd just moved all the furniture around again. Since my time is split between scrim and drawing and painting, this accommodates all three. The table against the window is where the drawing happens, the super heavy duty drafting table against the wall holds the scope and scrim stuff, and the easel and paint drawers are there too. I just push the chair around from one station to another depending on what I need to work on! -Katherine |

|

| Bookmarks |

|

|